Supply Chain Risk & Resilience Assessment

A Consulting-Style Analysis of Patagonia’s Black Hole® Pack

Case Study Overview

Patagonia’s sustainability-first sourcing model makes it an ideal case for examining how ethical and environmental constraints interact with supply chain risk and resilience.

This project provides an executive-style assessment of concentration, logistics exposure, and operational trade-offs within a global supply network.

Problem

How resilient is a sustainability-driven supply chain when multiple tiers depend on concentrated sourcing and long-haul logistics?

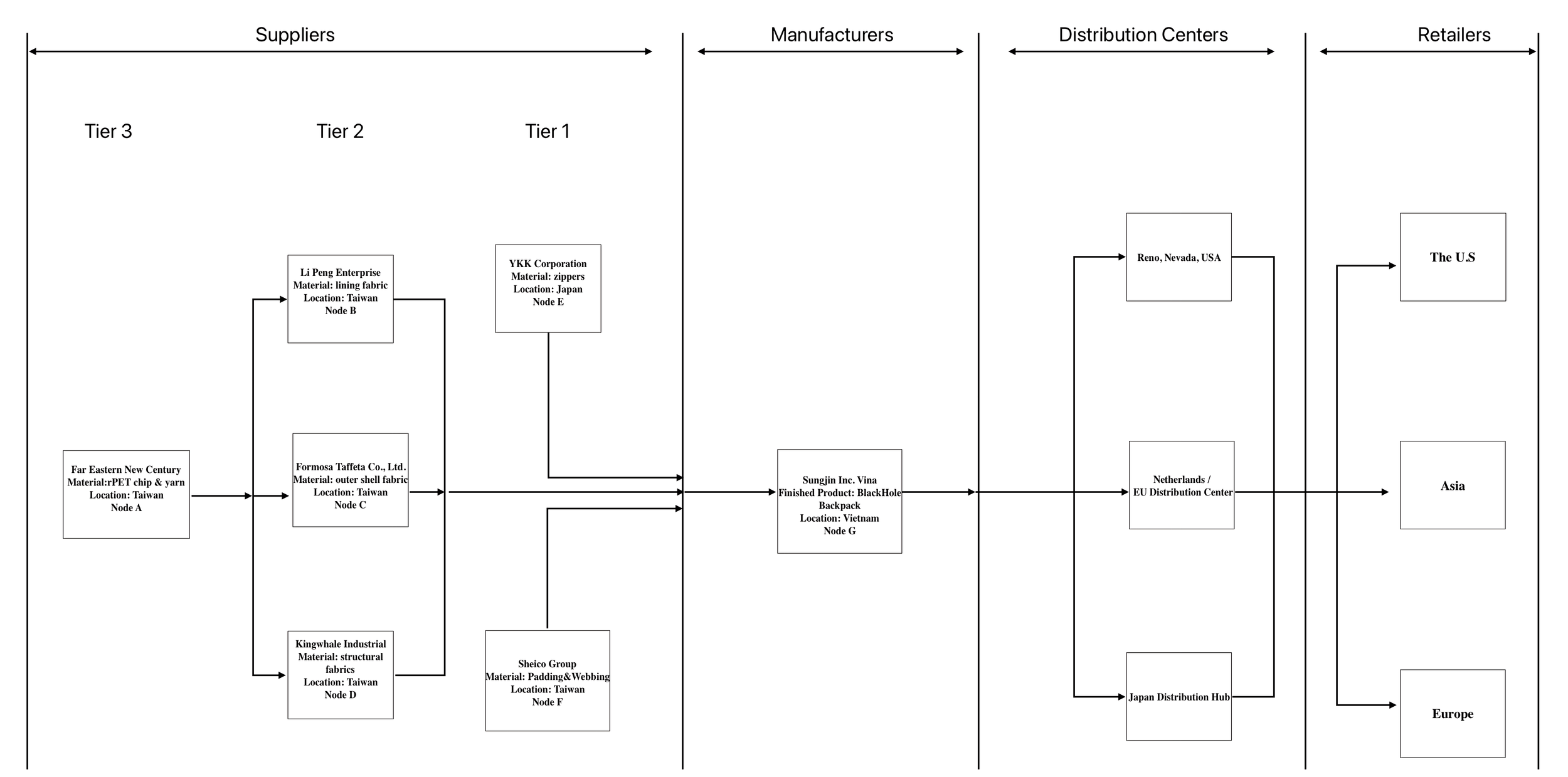

Supply Chain Structure

Analytical Focus

Supplier and geographic concentration

Manufacturing and logistics dependency

System-level risk amplification

Operational constraints introduced by sustainability standards

Key Insights

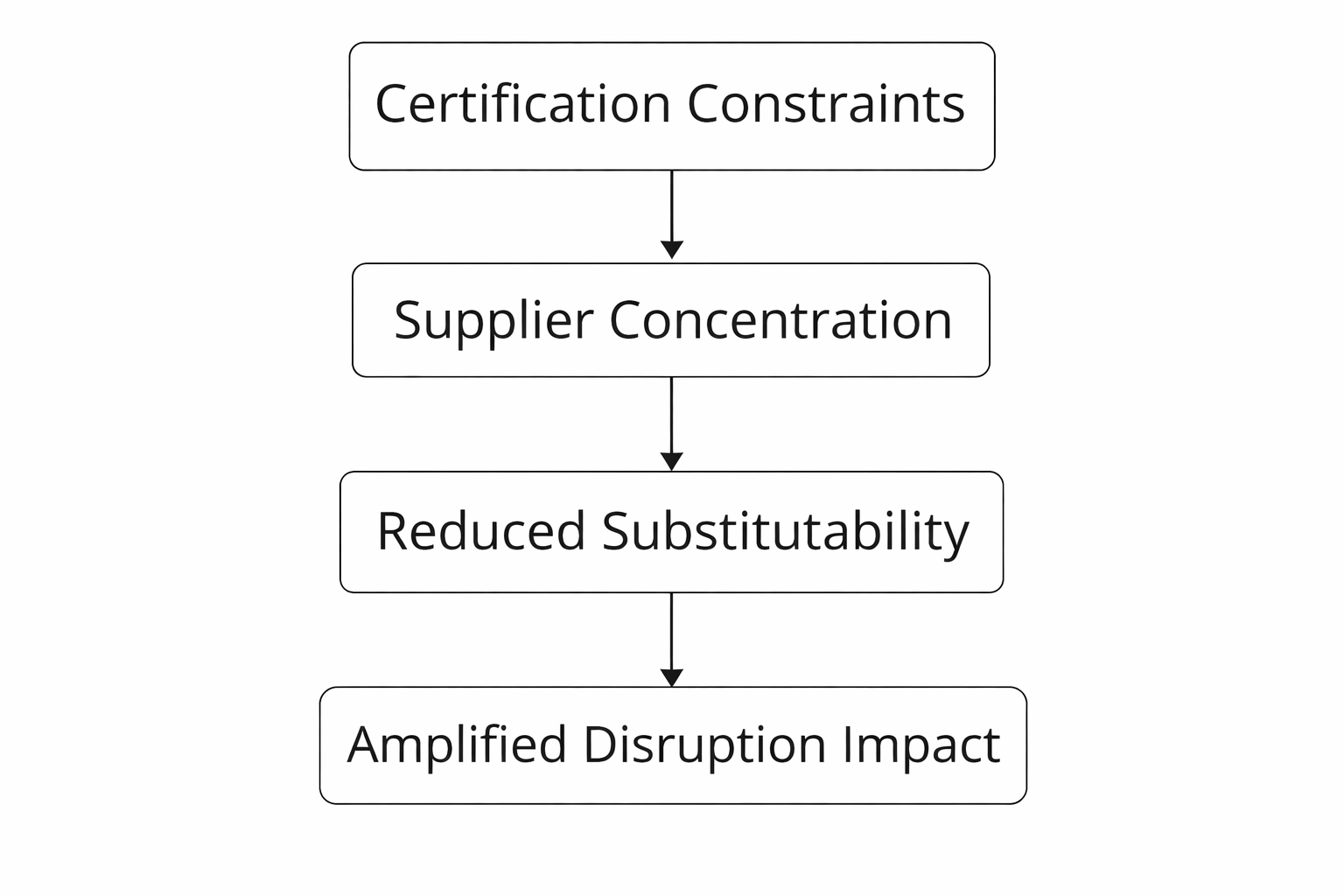

Risk Amplification Mechanism

Supplier and geographic concentration amplify systemic risk

When multiple supply chain tiers rely on a narrow set of certified suppliers within the same region, disruptions propagate quickly across the entire system.Sustainability constraints reduce substitutability under disruption

Environmental certification requirements and ethical sourcing standards limit the ability to switch suppliers or logistics modes in response to shocks.Long-haul logistics magnify disruption impact

An emissions-driven reliance on ocean freight increases exposure to port congestion, climate events, and global shipping volatility, extending recovery time after disruptions.

Strategic Takeaways

Resilience must be designed alongside sustainability goals

Sustainability improves long-term performance only when resilience and flexibility are explicitly incorporated into supply chain design.Diversification is effective only when constraints are addressed

Supplier and manufacturing diversification require parallel expansion of certified capacity; otherwise, concentration risk persists despite geographic spread.Proactive risk monitoring is a strategic necessity

Early detection of geopolitical, climate, and logistics risks enables faster response in tightly constrained supply chains.